The construction industry is a key player in the global economy, providing essential infrastructure and housing that supports communities and businesses. However, the costs associated with construction materials, particularly metals, play a significant role in shaping the industry's landscape. In this article, we’ll explore the relationship between metal prices and the construction industry, examining how fluctuations in metals news https://metalswire.net/ can impact construction costs and projects.

The Role of Metals in Construction

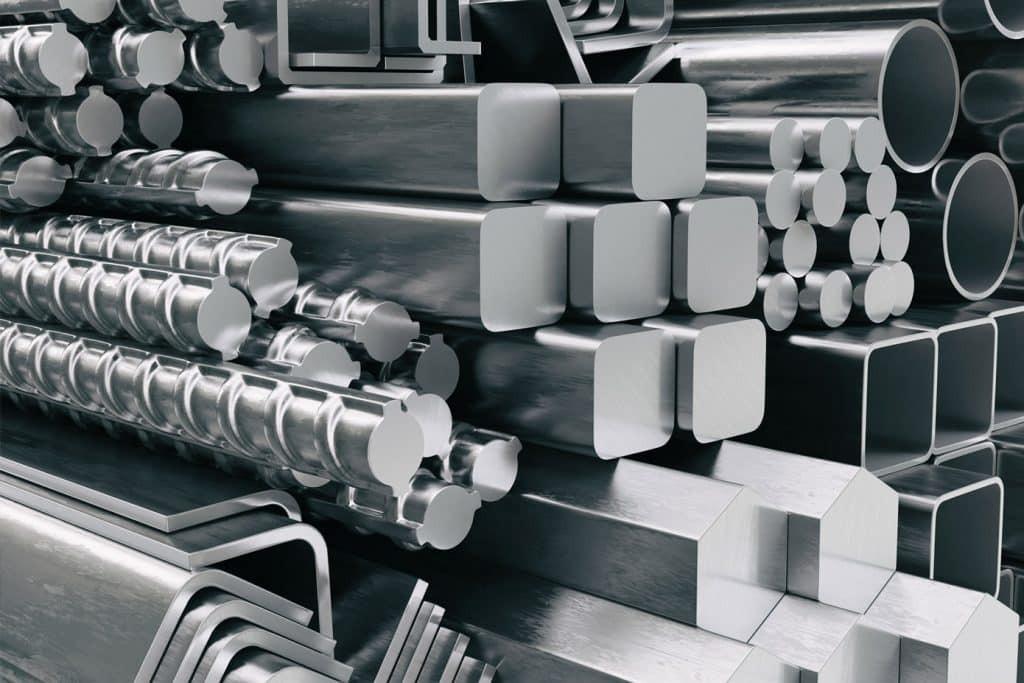

Metals are an integral part of the construction industry, used in a variety of applications ranging from structural components to finishing touches. Common metals like steel, aluminum, copper, and zinc are used in everything from building frames to plumbing and electrical wiring. The versatility, durability, and strength of metals make them indispensable in modern construction projects.

Steel, in particular, is the backbone of the construction industry, widely used for beams, columns, reinforcement bars, and steel plates. Aluminum is essential for window frames, roofing, and facades, while copper is used for wiring and piping. As a result, any shift in metal prices can significantly affect both the cost and timeline of construction projects.

How Metal Prices Affect the Cost of Construction

Metal prices are subject to a variety of factors, including supply and demand, geopolitical events, and global economic conditions. When the price of metals rises, construction costs often follow suit, as contractors and developers must account for higher material expenses.

For example, fluctuations in steel prices can affect everything from the price of new buildings to the cost of renovations. If steel prices rise due to increased demand or supply shortages, construction companies might need to increase their bids to offset the higher costs, leading to increased overall project expenses. In some cases, this could cause delays in construction as companies adjust their budgets or seek alternative materials.

The Influence of Global Markets and Geopolitics on Metal Prices

The construction industry doesn’t exist in isolation from global economic trends, and the price of metals is heavily influenced by international markets and geopolitical tensions. For example, trade wars, sanctions, or natural disasters can disrupt metal supply chains, causing price spikes. In the case of the recent steel tariffs implemented by the U.S. government, the cost of steel products rose due to limited imports, affecting construction companies across the country.

Similarly, the global demand for certain metals, especially steel, is affected by the growth of industries such as automotive, infrastructure, and renewable energy. When demand increases in these sectors, metal prices tend to rise, which can directly impact construction project budgets.

Tracking Metal Prices Through Metals News

For those in the construction industry, staying updated on metals news is crucial for forecasting costs and planning projects effectively. Metals news provides the latest information on metal prices, production levels, and market forecasts, helping contractors make informed decisions about material sourcing and cost management.

For example, if a construction manager is aware of a predicted rise in steel prices, they can plan ahead by purchasing materials in bulk or considering alternatives like wood or concrete. Monitoring metals news also allows construction firms to adjust their bids based on market conditions, ensuring that they remain competitive while maintaining profitability.

Additionally, metals news often includes insights into supply chain disruptions, such as delays in metal delivery or price hikes due to global shortages. This can help construction professionals better anticipate challenges and minimize risks in their projects.

The Impact of Metal Price Volatility on Project Timelines

The volatility of metal prices can create uncertainty in the construction industry. Sudden spikes or drops in metal prices can lead to delays, cost overruns, or rethinking of project designs. For instance, if prices surge during the planning stage, a developer may need to revise their budget or project specifications to accommodate the increased cost of materials.

This volatility is particularly challenging for large-scale infrastructure projects, which may span several years. A construction company might lock in prices for materials at the start of the project, only to face unexpected price hikes midway through. Such challenges require flexibility and careful planning, as project managers need to find ways to absorb additional costs or adjust their schedules to minimize delays.

How Construction Companies Can Mitigate the Impact of Metal Price Changes

Given the volatility of metal prices, construction companies must adopt strategies to mitigate the impact on their operations. One approach is to secure long-term contracts or price agreements with suppliers, locking in rates before they increase. By establishing relationships with reliable suppliers, construction firms can gain more control over their material costs and reduce the risk of price spikes.

Another strategy is to diversify the types of materials used in construction. While metals are essential, they are not always the only option for every application. For instance, contractors may explore alternative materials like composite products or timber, which can offer cost savings without compromising the integrity of the project.

Additionally, it’s important for construction companies to invest in technology that allows for more precise cost estimations. Advanced project management software can help firms track material prices in real time, identify potential cost overruns, and optimize resource allocation.

The Future of Metal Prices in Construction

The future of metal prices in the construction industry is uncertain, but experts predict that demand for metals will remain strong due to the ongoing expansion of global infrastructure and industrial development. With trends like the rise of green building practices and the construction of smart cities, metals like steel, copper, and aluminum will continue to be in high demand.

At the same time, advancements in metal production techniques and recycling technologies may help mitigate price fluctuations. As the industry adapts to global economic shifts and environmental pressures, it is likely that new strategies will emerge to balance the costs of metals with the need for sustainable construction.

Conclusion

The relationship between metal prices and the construction industry is indeed symbiotic. The demand for metals in construction drives global markets, while shifts in metal prices directly influence project budgets, timelines, and strategies. Staying informed through metals news is crucial for construction professionals to navigate this dynamic landscape and make well-informed decisions that ensure the success of their projects. By understanding the impact of metal price fluctuations and adopting smart strategies, the construction industry can thrive despite the challenges posed by market volatility.