Protective cable conduits are essential for safeguarding wiring systems against external elements like moisture, abrasion, and physical impact. When choosing between metal and plastic conduits, understanding their properties is key to ensuring long-term reliability and performance. While both have their advantages, metal conduits stand out for their unmatched durability and versatility, making them the preferred choice in many applications.

Strength and Durability

- Resistance to Physical Impact

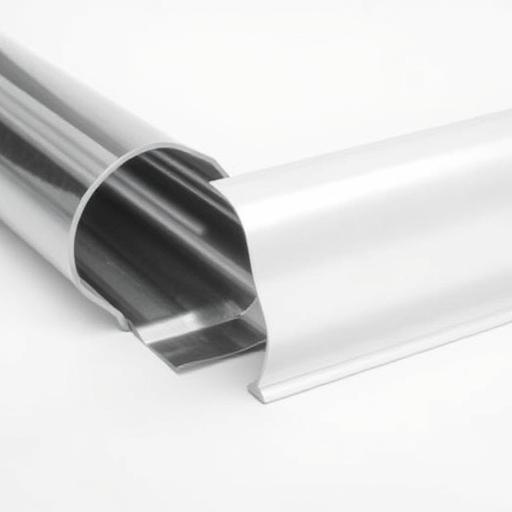

- Metal Conduits: Made from materials like galvanized steel or aluminum, metal conduits can withstand heavy physical impacts without deforming. This makes them ideal for high-traffic areas and industrial environments.

- Plastic Conduits: Though flexible, plastic conduits are prone to cracking or breaking under significant stress, reducing their lifespan in demanding conditions.

- Fire Resistance

- Metal Conduits: Being non-combustible, metal conduits offer excellent fire resistance, ensuring added safety in applications prone to fire hazards.

- Plastic Conduits: Most plastic conduits are combustible and can emit toxic fumes when exposed to high temperatures, posing a safety risk.

Environmental Protection

- Moisture and Corrosion

- Metal Conduits: Modern metal conduits are often coated with corrosion-resistant materials, making them suitable for wet and outdoor environments.

- Plastic Conduits: While inherently resistant to corrosion, they may become brittle and degrade under prolonged exposure to UV rays and extreme weather conditions.

- Temperature Tolerance

- Metal Conduits: With higher tolerance to temperature extremes, metal conduits maintain their integrity in both hot and cold environments.

- Plastic Conduits: Susceptible to warping or becoming brittle in extreme temperatures, limiting their use in certain climates.

Application Versatility

- Industrial and Commercial Settings

Metal conduits excel in environments like factories, warehouses, and large commercial buildings where durability and fire safety are critical. - Residential Use

While plastic conduits are commonly used in residential setups for cost-effectiveness, metal conduits are increasingly favored for areas requiring enhanced safety and durability. - Electromagnetic Interference (EMI) Shielding

Metal conduits provide natural shielding against EMI, protecting sensitive electronic equipment from signal interference. Plastic conduits lack this capability, making them unsuitable for such applications.

Cost vs. Value

While plastic conduits may initially seem more economical, the long-term benefits of metal conduits often outweigh the cost difference:

- Longevity: Metal conduits typically have a much longer lifespan, reducing replacement and maintenance costs.

- Safety: Enhanced fire resistance and structural strength ensure peace of mind in critical applications.

Conclusion

When it comes to protective cable conduits, the choice between metal and plastic boils down to application requirements. For scenarios demanding maximum durability, fire resistance, and EMI shielding, metal conduits are the clear winner. Although plastic conduits may work well for lightweight and temporary installations, the robustness and reliability of metal make it the superior choice for critical infrastructure.

Investing in metal protective cable conduits ensures not only better performance but also a safer and longer-lasting solution for your wiring systems.

Schneider Electric Products: Essential Solutions for Infrastructures and Big Industrial Projects

Building the Future: Schneider Electric Products for Industrial and Architectural Excellence